Kwilizwe elikhawulezayo lenkqubela phambili yeemoto, ukuhlala uqhagamshelwe kuye kwaba yinto efunekayo kubaqhubi kunye nezithuthi zabo.Enye yezinto ezininzi ezintsha eziziswa kukuhlangana kobunjineli beemoto kunye nombane kukusetyenziswa kwebhodi yesekethe eprintiweyo (PCB) iziqhagamshelo kwiimoto kunye nezithuthuthu.Ezi ziqhagamshelo zidlala indima ebalulekileyo ekuphuculeni uqhagamshelwano, ukuphucula ukusebenza kunye nokuqinisekisa amava okuqhuba akhuselekileyo nathembekileyo.Kule bhlog, siza kuphanda ngokubalulekaizihlanganisi PCB zombanekwiimoto kunye nezithuthuthu.

1. Ukuhanjiswa komqondiso osebenzayo:

Ukuhanjiswa kombane okusebenzayo kusembindini woqhagamshelo lwemoto.Izihlanganisi zePCB ziyilelwe ngokukodwa ukunika uqhagamshelo oluthembekileyo nolukhuselekileyo phakathi kwamacandelo ahlukeneyo e-elektroniki kwizithuthi ezinjengezoluvo, iiyunithi zolawulo kunye neziboniso.Ngokuqinisekisa ukuhanjiswa okungenamthungo kwemiqondiso yombane, ezi ziqhagamshelo zithintela ukulahleka kwedatha okanye urhwaphilizo, zenza kube lula ukusebenza kunye nokuphucula ukhuseleko ezindleleni.

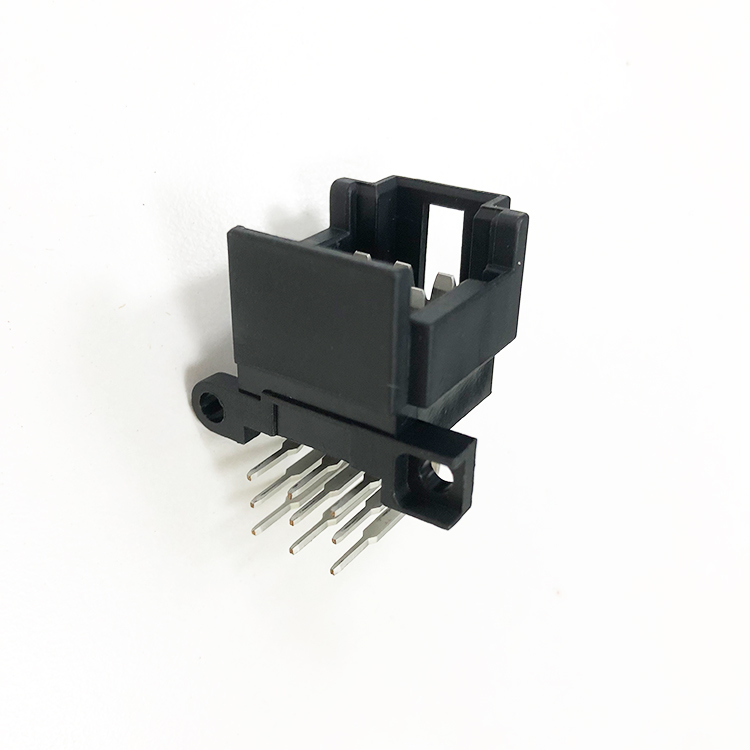

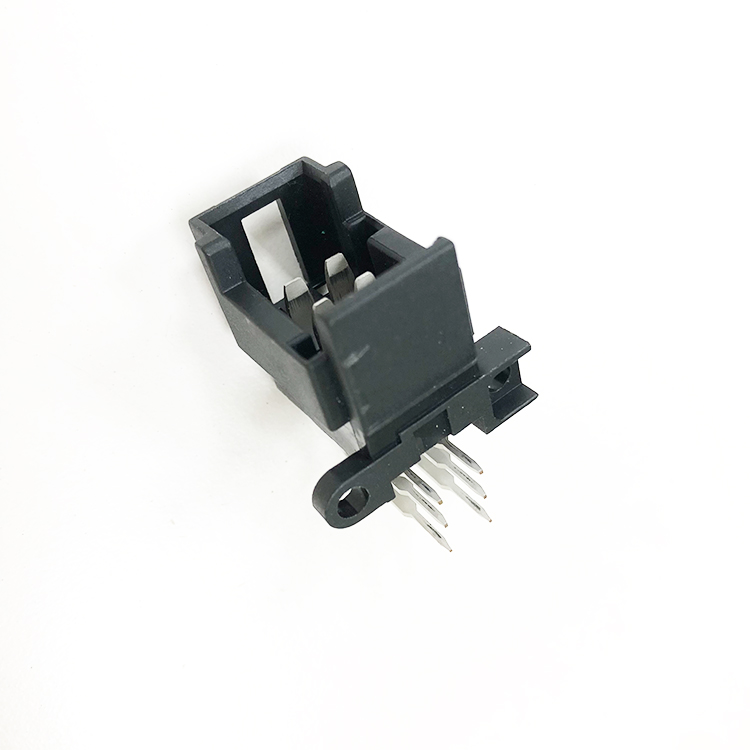

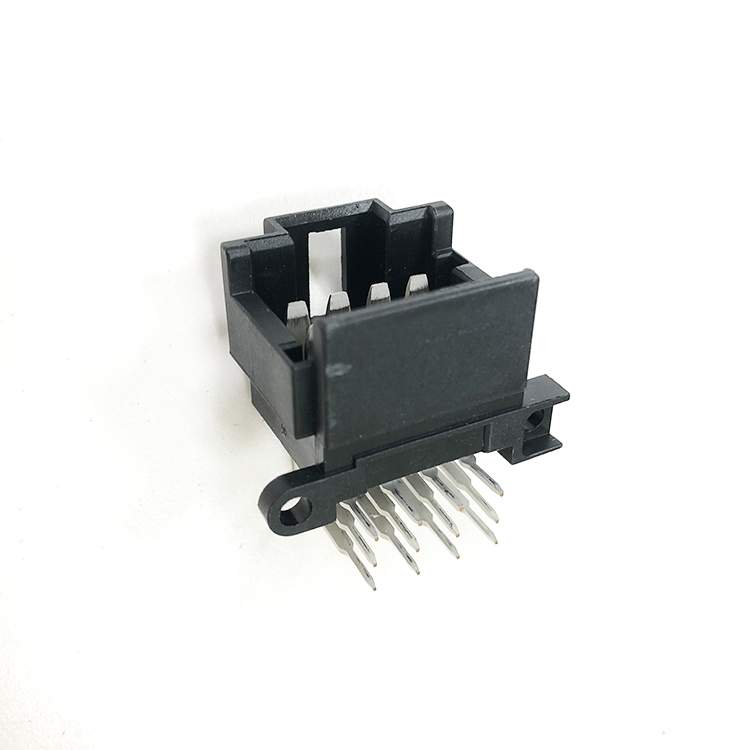

2. Uyilo olubambeneyo kunye nokwenza ngcono indawo:

Iimoto kunye nezithuthuthu zihlala zisebenza kwindawo enendawo encinci.Uyilo oludityanisiweyo lweziqhagamshelo zePCB lusebenzisa isithuba ngokufanelekileyo kwaye luqinisekisa ukusebenza ngokupheleleyo kweenkqubo zombane ngaphandle kokubeka esichengeni uyilo lwesithuthi.Ezi ziqhagamshelo zinokudityaniswa ngokungenamthungo kwiinkqubo zombane ezikhoyo ukuze kube lula ukufakela nokugcinwa.

3. Ukuxhathisa ukungcangcazela kunye nokuqina:

Izithuthi zihlala ziphantsi kokungcangcazela kunye nokothuka endleleni.Izihlanganisi ze-PCB ziyakwazi ukumelana nezi meko zinzima, ziqinisekisa ukhuselekouqhagamshelo lombanekungakhathaliseki ukuphazamiseka kwangaphandle.Ezi ziqhagamshelo zakhiwe ngokuqinileyo ngokuxhathisa ukungcangcazela okugqwesileyo ukuthembeka kunye nobomi obude.

4. Ukwenza ngokwezifiso kunye nokuguquguquka:

Uluhlu olubanzi lweenkqubo zombane zeemoto zifuna izihlanganisi ezinokuthi zenziwe ngokwezifiso ukuhlangabezana neemfuno ezithile.Izihlanganisi ze-PCB zibonelela ngokuguquguquka kuyilo, ulungiselelo loqhagamshelwano, kunye noqwalaselo lwephini, lubenza balungele iindidi ezahlukeneyo.izicelo zeemoto.Oku kuguquguquka kuqinisekisa ukuhlanganiswa okungenamthungo kwiinkqubo zombane eziyinkimbinkimbi, okwenza uxhulumaniso olusebenzayo kunye nokuphucula ukusebenza kwesithuthi ngokubanzi.

5. Iimpawu zokhuseleko ezongeziweyo:

Ukhuseleko lubaluleke kakhulu kwishishini leemoto kunyeizihlanganisi PCB zombaneyenza igalelo elibalulekileyo ekuphunyezweni kweempawu zokhuseleko oluphezulu.Ezi ziqhagamshelo ziququzelela ukuhlanganiswa kweenkqubo zokukhusela ezinqambileyo ezifana neenkqubo zokunqanda ukutshixa (ABS), ulawulo lozinzo lwe-elektroniki (ESC) okanye iinkqubo zokuncedisa umqhubi ophezulu (ADAS).Ngokwenza ukuhanjiswa okusebenzayo kwemiqondiso ebalulekileyo, ezi ziqhagamshelo zidlala indima ebalulekileyo ekuqinisekiseni ukusebenza kweempawu zokhuseleko kunye nokuphucula ukhuseleko lokuqhuba ngokubanzi.

6. UQhagamshelwano oluPhuculayo:

Njengeishishini leemotoihambela phambili kwixesha leemoto ezikrelekrele, eziqhagamshelweyo, izihlanganisi zePCB zombane zibaluleke ngakumbi.Izithuthi zexesha elizayo ziya kuxhomekeka kakhulu kunxibelelwano oluphambili, kubandakanywa unxibelelwano olungenazingcingo, iGPS kunye nezakhono zokuqhuba ezizimeleyo.Izihlanganisi ze-PCB ziya kusebenza njengentsika yale misebenzi, ivumela unxibelelwano olungenamthungo phakathi kwamacandelo ahlukeneyo ezithuthi kunye neenkqubo zangaphandle.

Ukudityaniswa kweziqhagamshelo zePCB zombane kwiimoto kunye nezithuthuthu kuguqukileuqhagamshelwano lweemotoiteknoloji.Ngokuhambisa umqondiso osebenzayo, uyilo oludibeneyo, ukuqina, ukuguquguquka kunye negalelo kwiimpawu ezikhuselekileyo ezikhuselekileyo, ezi ziqhagamshelo ziqinisekisa amava okuqhuba akhuselekileyo, akhuselekileyo kwaye axhunyiwe.Njengoko ishishini liqhubeka nokuvela, sinokulindela ukudityaniswa okuntsonkothileyo kunye nezihamba phambili zombane zePCB ukuqhuba ikamva lobuchwephesha beemoto.

Ixesha lokuposa: Jul-18-2023